Selecting the right material for custom towels can significantly impact their performance, durability, and overall user satisfaction. Whether you're ordering custom towels for your hotel, spa, sports facility, or personal use, understanding the various fabric options and their characteristics is crucial for making an informed decision. This comprehensive guide will explore everything you need to know about custom towel materials, helping you make the best choice for your specific needs.

Cotton remains the most popular choice for custom towels, offering excellent absorbency and comfort. Egyptian cotton, known for its superior quality, features extra-long staple fibers that create incredibly soft and durable custom towels. Turkish cotton, another premium option, provides rapid drying capabilities while maintaining its plush feel over time. Pima cotton, grown in the United States, offers similar benefits to Egyptian cotton at a more accessible price point.

Modern custom towels sometimes incorporate synthetic materials like microfiber or polyester blends. These materials can enhance durability and speed up drying time. Microfiber custom towels are particularly popular in sports facilities due to their lightweight nature and quick-drying properties. However, they may not provide the same luxurious feel as pure cotton options.

Grams per Square Meter (GSM) is a crucial metric when selecting custom towels. Lower GSM ratings (300-400) produce lighter, quicker-drying towels ideal for gym or kitchen use. Medium GSM (400-600) offers a good balance of durability and absorbency, perfect for everyday custom towels. Luxury custom towels typically feature high GSM ratings (600-900), delivering maximum absorbency and a premium feel.

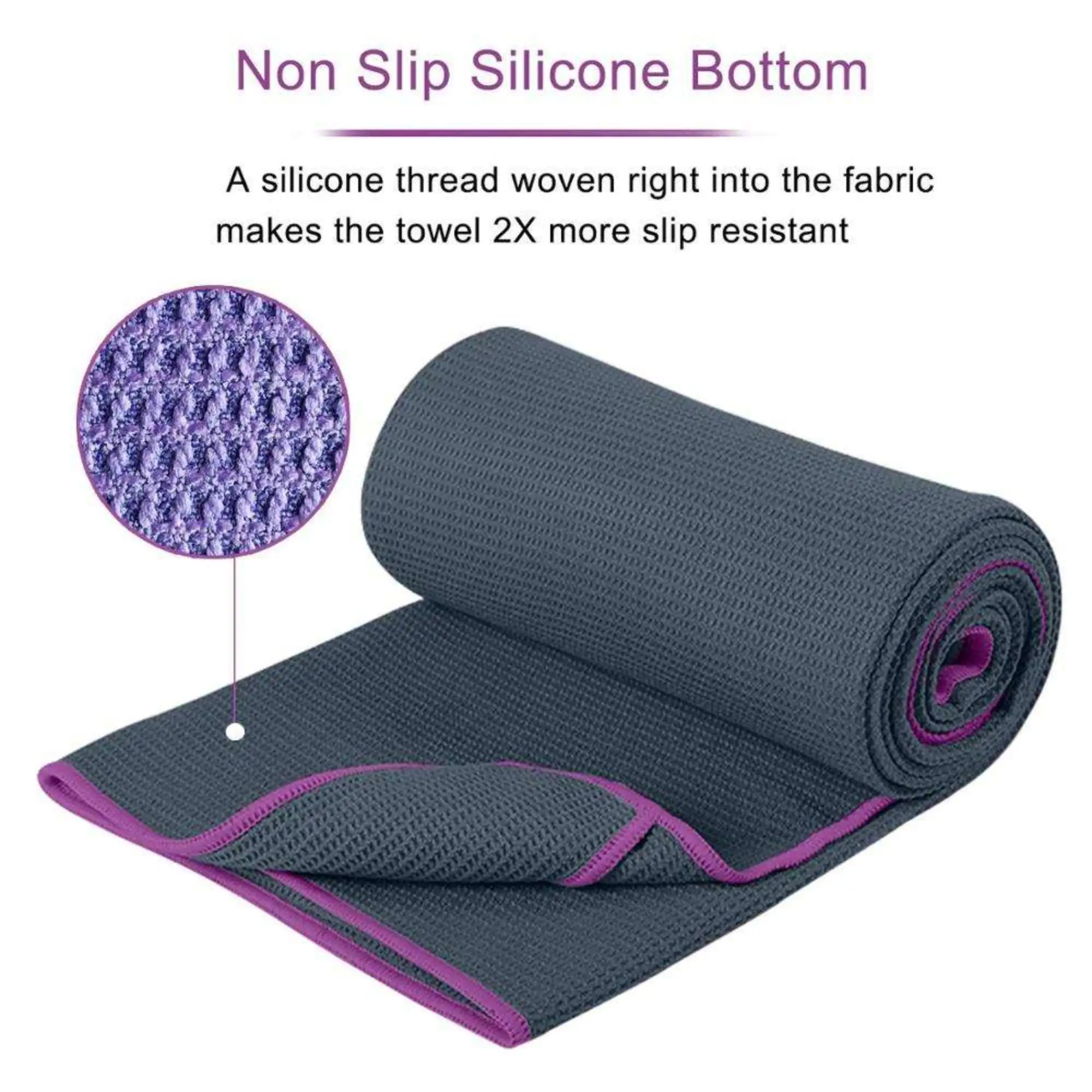

The weave pattern significantly impacts a towel's performance and appearance. Terry cloth, characterized by its looped pile, is the most common choice for custom towels due to its excellent absorbency. Waffle weave patterns create a distinctive texture that enhances drying efficiency while reducing bulk. Zero-twist construction produces exceptionally soft custom towels that maintain their plushness through repeated washing.

When investing in custom towels, consider the fiber strength of different materials. Long-staple cotton fibers resist pilling and maintain their integrity through numerous wash cycles. Custom towels made with quality materials typically feature double-stitched edges and reinforced corners, extending their lifespan. The initial investment in premium materials often pays off through reduced replacement costs over time.

Different materials demand varying care approaches. Cotton custom towels generally require gentle washing in warm water and tumble drying on medium heat. Synthetic blends often withstand higher temperatures and more aggressive washing methods. Consider your facility's laundry capabilities and maintenance resources when selecting custom towel materials.

Sustainable custom towels are increasingly important for environmentally conscious businesses. Organic cotton, grown without harmful pesticides, offers a responsible choice for custom towels. Bamboo blends provide another eco-friendly option, combining natural antibacterial properties with sustainable production methods. Some manufacturers now offer custom towels made from recycled materials, helping reduce environmental impact.

The environmental impact extends beyond material selection to include manufacturing processes. Look for custom towels produced using water-efficient methods and eco-friendly dyes. Some manufacturers employ closed-loop systems that minimize water waste and chemical use during production. These sustainable practices can enhance your brand's environmental credentials while delivering high-quality custom towels.

Different materials accept customization methods differently. Cotton custom towels typically work well with embroidery and traditional printing methods. Synthetic materials might require specific decoration techniques to ensure lasting results. Consider how your chosen material will interact with your desired branding elements, including logos, text, and decorative elements.

Material choice affects color vibrancy and longevity in custom towels. Natural fibers like cotton accept dyes well but may fade gradually with use. Synthetic materials often maintain their color better but might offer limited color options. Consider your branding requirements and how different materials will maintain their appearance over time.

The lifespan of custom towels depends on their material quality and usage frequency. High-quality cotton towels typically last 2-3 years with proper care, while synthetic blends might need replacement every 1-2 years. Regular inspection for wear and tear helps determine optimal replacement timing.

Medium to high GSM cotton towels generally provide the best foundation for embroidered logos. The dense fiber structure supports detailed needlework while maintaining durability through washing. Consider Egyptian or Turkish cotton for premium custom towels with embroidered designs.

While eco-friendly custom towels may have a higher initial cost, their durability and positive environmental impact often justify the investment. Sustainable materials typically offer better longevity, reducing long-term replacement expenses while supporting environmental responsibility.

To maintain color vibrancy, wash custom towels in cool to warm water, avoid harsh bleaching agents, and dry on medium heat. Separate light and dark colors during washing, and consider using color-protecting detergents specifically formulated for custom towels.

Hot News

Hot News2024-03-08

2024-03-08

2024-03-08

2024-03-08

2024-03-08